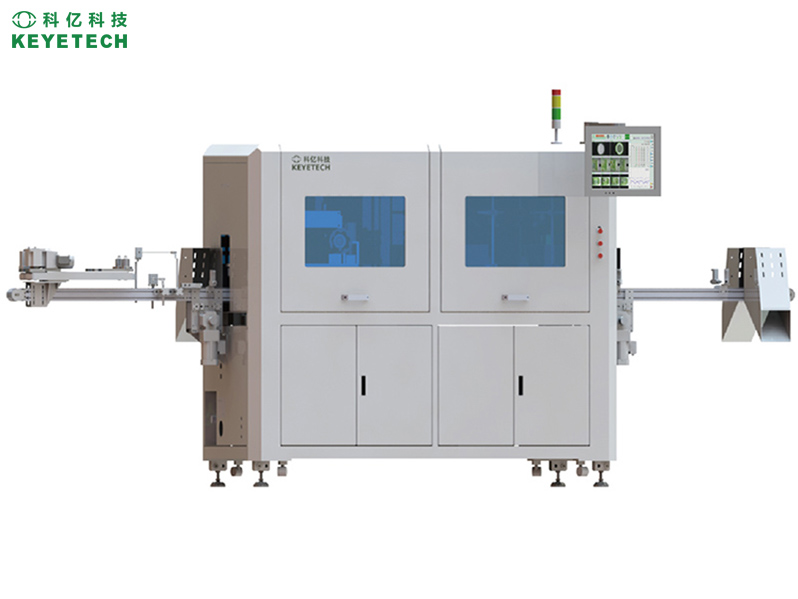

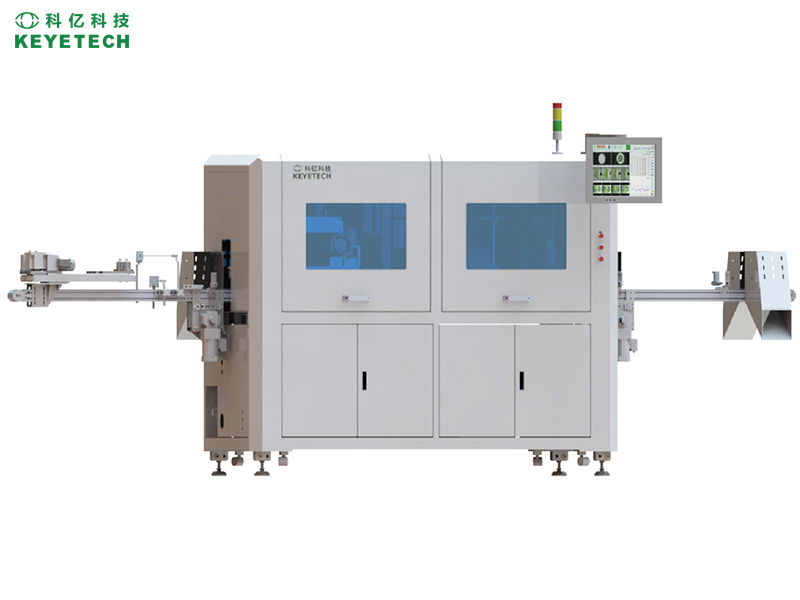

Automatizado Máquina de inspección IML es la detección en línea de alta velocidad, que mejora la eficiencia y precisión de la detección y reduce los costos laborales. Adopta hCámaras industriales de alto píxel para un reconocimiento preciso, con diseño de cantidad de cámaras bajo demanda, precisión de 0,1 mm y velocidad personalizable según las necesidades de detección. La máquina es cCompatible con probar múltiples especificaciones de productos, ahorrando costos, puede dDetecte y elimine defectos como caracteres faltantes, etiquetas faltantes, desplazamiento de etiquetas, borrosidad, lectura de códigos QR, lectura de códigos de barras, puntos negros, diferencia de color, impurezas, etc. de las etiquetas en línea.

Con el hardware y el software de desarrollo propio, esta inspección IML es muy simple y fácil de operar; solo necesita unas pocas muestras defectuosas para capacitarse en nuestra plataforma de capacitación de IA; puede actualizar su software de inspección usted mismo o nuestro equipo. Tanto el sistema de IA como la plataforma de formación se actualizan online con nuestro propio servidor.

![]()

Principales características

- Cámara industrial de alto píxel

- Lente industrial de alta resolución

- Fuente de luz estroboscópica LED de alto brillo

- Algoritmo de inteligencia artificial (Al)

- Unidad de procesamiento informático GPU de alto rendimiento

- Pantalla táctil industrial de alta resolución.

- Sistema de inspección de calidad de IA personalizable

![]()

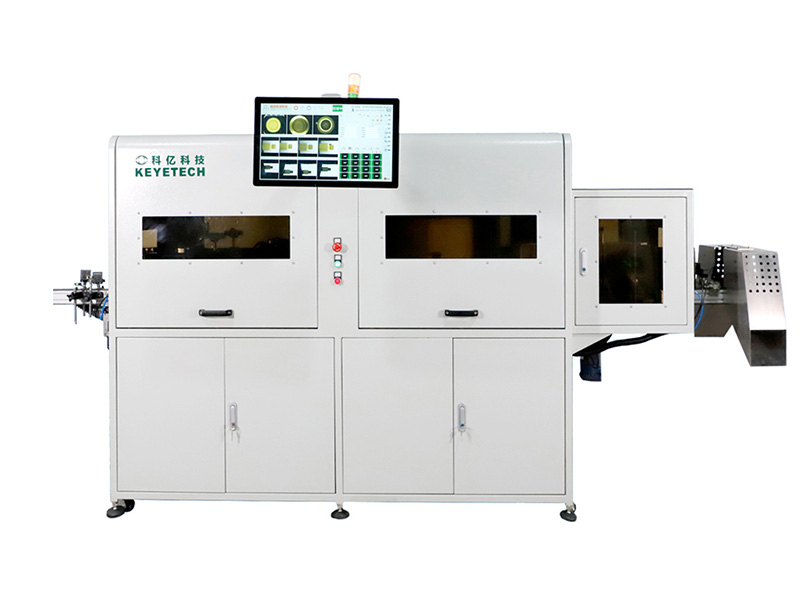

Especificaciones principales

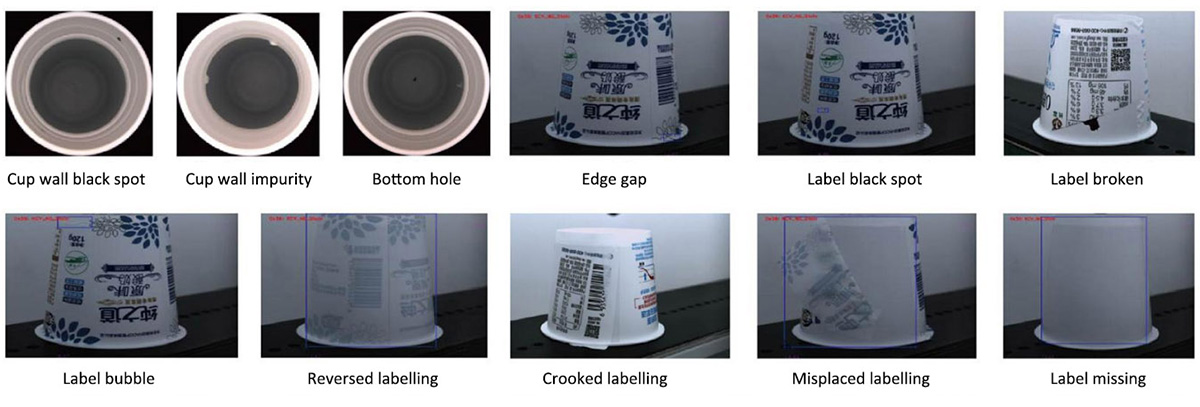

| Tipos de defectos | Mal etiquetado, como etiquetas superpuestas, torcidas, dislocadas, con burbujas, arrugadas y también con manchas negras. |

| Posiciones de inspección | Etiquetas en el cuerpo de la taza, boca, pared interior y fondo exterior. |

| Inspeccionar velocidad | 150 unidades ~ 300 unidades/minuto |

| Precisión | 0,1 mm |

| Tasa de precisión | >99,9% |

| Aire comprimido | 0,5 MPa ~ 0,8 MPa |

| Peso neto | Alrededor de 260 kg. |

| Dimensión | 1277*670*1634mm |

| Fuerza | 3~6Kw |

Configuraciones principales

| Descripción | Modelo/Marca | Cantidad |

| Serie de software de algoritmos de IA | KVIS 16 | 1 juego |

| Plataforma de servicios en la nube de IA | Keye Tech | 1 juego |

| Cámara industrial | KeyeTech/HIKVISION | 6 piezas (personalizables) |

| Lente plana | HIKVISIÓN | 6 piezas (personalizables) |

| Fuente de luz estroboscópica | Keye Tech | 1 juego |

| Sensor fotoeléctrico | ENFERMO (Alemania) | 1 pieza (personalizable) |

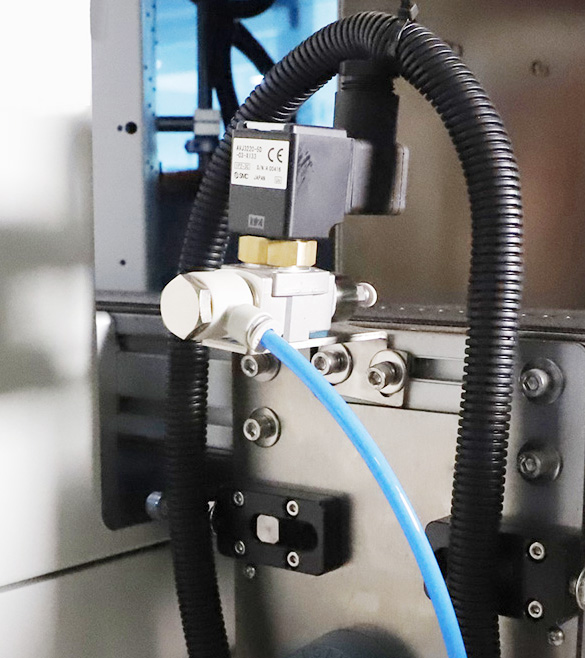

| Válvula electromagnética | SMC (Japón) | 1 pieza (personalizable) |

| Kit de potencia industrial | Serie LRS | 1 juego |

| Panel de control principal | KY-INS-V21 | 1 juego |

| SOCIEDAD ANÓNIMA | RTS-3060 | 1 juego |

| Unidad de computación integrada | KYEBS-1684 | 1 juego (opcional) |

| Sistema de interfaz de usuario HID | 21 pulgadas | 1 juego |

| Estructura mecánica | Acero inoxidable 304 | 1 juego |

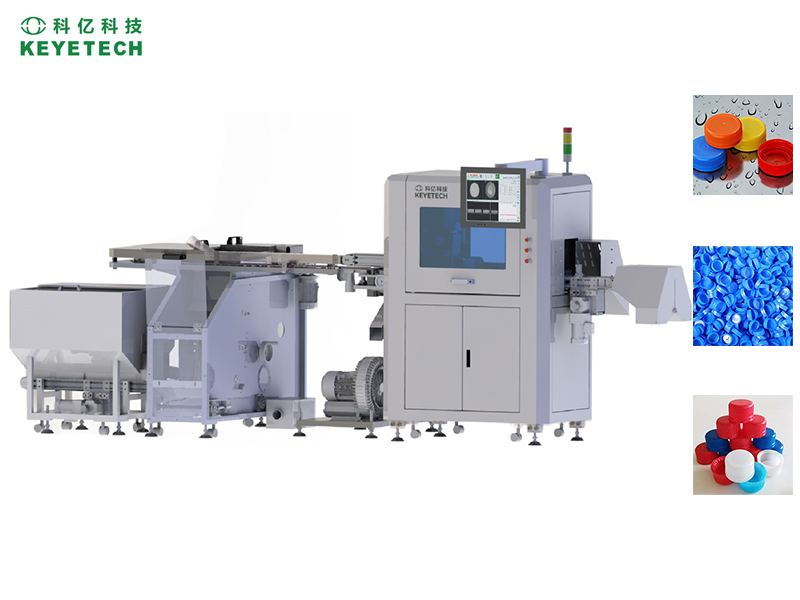

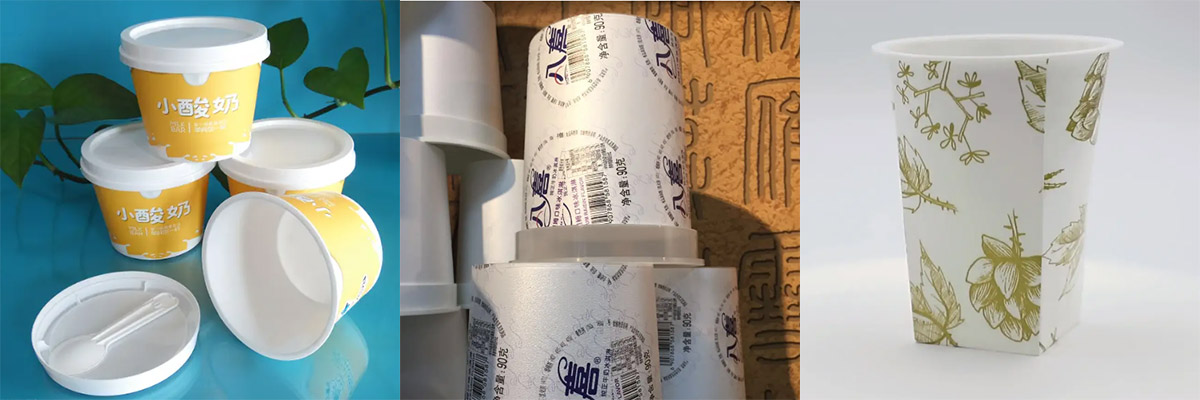

Aplicaciones de productos

La máquina automática de inspección de defectos de impresión IML de KeyeTech puede inspeccionar los defectos IML de los vasos de papel, plástico y plástico.

Principales ventajas técnicas

Cámara industrial ocultadaUna cámara industrial de alta precisión de desarrollo propio junto con una lente HID famosa en el campo, equipada con un sistema de algoritmo KeyeTech AI, puede lograr un efecto de imagen visual de alta velocidad y alta precisión.

Cámara industrial ocultadaUna cámara industrial de alta precisión de desarrollo propio junto con una lente HID famosa en el campo, equipada con un sistema de algoritmo KeyeTech AI, puede lograr un efecto de imagen visual de alta velocidad y alta precisión. Fuentes de luz personalizadasFuente de luz LED estroboscópica de desarrollo propio, diseña la fuente de luz de uso especial en función de diferentes defectos de apariencia de carácter. La fuente de luz de la cavidad integrada puede obtener imágenes más uniformes de las paredes laterales.

Fuentes de luz personalizadasFuente de luz LED estroboscópica de desarrollo propio, diseña la fuente de luz de uso especial en función de diferentes defectos de apariencia de carácter. La fuente de luz de la cavidad integrada puede obtener imágenes más uniformes de las paredes laterales. Sistema de control automáticoLa unidad de procesamiento GPU de alta eficiencia y el software de interacción persona-computadora HID personalizable funcionan junto con una válvula electromagnética de alto rendimiento para lograr un control totalmente automatizado.

Sistema de control automáticoLa unidad de procesamiento GPU de alta eficiencia y el software de interacción persona-computadora HID personalizable funcionan junto con una válvula electromagnética de alto rendimiento para lograr un control totalmente automatizado. Sistema de IA KeyeTechEl sistema de software KeyeTech que adopta el algoritmo de aprendizaje profundo de IA es la principal ventaja técnica de la máquina, ya que alcanza imágenes y reconocimiento de defectos más precisos y rápidos, lo que mejora en gran medida la eficiencia.

Sistema de IA KeyeTechEl sistema de software KeyeTech que adopta el algoritmo de aprendizaje profundo de IA es la principal ventaja técnica de la máquina, ya que alcanza imágenes y reconocimiento de defectos más precisos y rápidos, lo que mejora en gran medida la eficiencia.

Preguntas más frecuentes

P: ¿Qué tipo de producto de impresión se puede inspeccionar?

R: Puede inspeccionar los defectos de los vasos de impresión IML.

P: ¿Qué tipo de defectos puede inspeccionar?

R: Esta máquina de inspección IML puede inspeccionar etiquetas defectuosas, como etiquetas torcidas, superpuestas, dislocadas, arrugadas y también con manchas en los espacios.

P: ¿Cuántos defectos puede detectar una máquina?

R: La cantidad de defectos es ilimitada y depende de la solicitud de detección del cliente.

P: ¿Cuántas cámaras hay equipadas en la máquina?

R: La cantidad de cámaras también se decide según los tipos y posiciones de defectos detectados; cuantos más tipos, mayor cantidad.

P: ¿Cuál es la definición de cámara?

R: La definición de la cámara y la lente dependen de su precisión defectuosa, es decir, la definición es diferente si la precisión defectuosa es de 0,2 mm y 0,5 mm.

P: ¿Si la cámara es de desarrollo propio o se compra a productores de cámaras profesionales?

R: La mayoría de las cámaras están diseñadas y desarrolladas por nosotros mismos, especialmente el sistema de inspección es un algoritmo de IA, la cámara debe coincidir con el sistema de IA.

P: ¿Las cámaras son las más importantes para la inspección?

R: La cámara es uno de los hardwares más importantes del equipo, el sistema de software de algoritmo de IA es la tecnología clave de la máquina.

P: ¿Cómo solucionar la instalación y el ajuste?

R: Le enviaremos nuestros ingenieros capacitados para su instalación y ajuste, lo que demora aproximadamente una semana.

P: ¿Es difícil utilizar su máquina? ¿Cómo capacitar a nuestra gente?

R: Sí, el sistema de la máquina es sofisticado, pero el control para usted es sencillo. Podemos capacitar a su personal en línea a través de la plataforma KeyeTech AI, lo cual es muy conveniente, y también puede enviar a su técnico a nuestra empresa para que aprenda, es gratis.

P: ¿Cuál es la garantía de su máquina? ¿Podrán suministrarnos los repuestos en el futuro?

R: Proporcionamos una garantía de un año para toda nuestra máquina, 3 años de garantía para hardware como la cámara, la lente y el sensor (si se daña por un uso personal inadecuado, el cliente deberá comprarnos). Somos responsables de los repuestos y el mantenimiento durante mucho tiempo.

P: ¿Qué información detallada debo proporcionar para obtener una cotización?

R: Los clientes deben proporcionarnos algunas respuestas exactas para solicitar una cotización:

- ¿Cuántos vasos IML se deben inspeccionar en total?

- ¿Cuál es el color y tamaño de las etiquetas? (necesita muestras o dibujo)

- ¿Cuántos defectos diferentes deben detectarse? (se necesitan muestras o dibujos)

- ¿Inspeccionar la posición objetivo o posiciones completas de 360°?

- ¿Cuál es la solicitud de velocidad de inspección?

- ¿Algún requisito especial para la precisión de la inspección?

- ¿Inspección en línea o fuera de línea? Si está en línea, ¿cómo combinar su máquina de vasos IML?

Las anteriores son parte de las preguntas que debemos discutir antes de la cotización; para una cotización exacta también necesitamos muestras de defectos físicos.

Observaciones: Para diseñar equipos que satisfagan las necesidades del cliente con mayor precisión, necesitamos tener una comunicación detallada entre ambas partes sobre los detalles de las pruebas, y solo entonces podremos confirmar los parámetros del equipo. Esto requiere algo de tiempo y proceso, y esperamos que los clientes con necesidades de compra puedan acudir a nuestra empresa para comunicarse e inspeccionarse cara a cara.